Manufacture Clothing in Vietnam

To manufacture clothing in Vietnam, I recommend you start by considering minimum order quantities (MOQ). Vietnam apparel manufacturing starts to make economical sense when you can produce 1,000 pieces per style per color. Any quantity less than that becomes risky. Allow me to explain.

MOQ is the abbreviation for minimum order quantity. MOQ is very important to a factory. Vietnam is a manufacturing country where the prevailing business strategy is based on offering low pricing and high volume. If you would like to produce less than 1,000 pieces in Vietnam for a low price, most factories will refuse your order. The simple reason is that they will lose money. Any factory that accepts to do low quantity, my advice is to be very careful.

MOQ is the abbreviation for minimum order quantity. MOQ is very important to a factory. Vietnam is a manufacturing country where the prevailing business strategy is based on offering low pricing and high volume. If you would like to produce less than 1,000 pieces in Vietnam for a low price, most factories will refuse your order. The simple reason is that they will lose money. Any factory that accepts to do low quantity, my advice is to be very careful.

Services We Offer

eBooks

Courses

Consultation

Factory Introductions

Factory Tours

Production A to Z

When is a good time to schedule a time to talk?

Please fill in our contact form below,

then click the submit button.

See you in Vietnam!

What is the minimum order quantity for apparel in Vietnam?

MCQ is the abbreviation for minimum color quantity. Assumption is that we are talking about solid colors. (If you are doing printed artwork then you need to work with the MPQ which is minimum print quantity.) If you are using solid color fabrics then the two smallest options for dyeing your fabric are 20 kg and 250 kg dye vats. Kg refers to the size of the dyeing vats used to die your fabric. 20 kg is the smallest and is used for make samples. With 20 kg of fabric you can make around 70 t-shirts. The next dye vat size is 250 kg which can make around 880 t-shirts. If you want 200 t-shirts then neither the 20 kg option nor 250 kg option works out well from a business point of view. More over the next size up in dye vat sizes is 1,000 kg which is the dye vat size brands like Nike work with. If you want a Nike manufacturing price then is it logical that you should be using the 1,000 kg dye vat size? With 1,000 kg of fabric dyed one solid color you can make around 3,500 t-shirts.

If you would like me to explain how I figured this out and how to work around this high MOQ then contact me. I will teach you the formulas and calculations and give you a solution for producing small quantity apparel in Vietnam.

If you would like me to explain how I figured this out and how to work around this high MOQ then contact me. I will teach you the formulas and calculations and give you a solution for producing small quantity apparel in Vietnam.

Another reason is: there are many large orders looking for a home in Vietnam that get precedence. Your small order will quickly be put on the back burner if you don't bird dog the factory. To manufacture clothing in Vietnam you need to meet the factories MOQ which is typically around 1,000 pieces per style per color. If you are doing less then I can introduce you to small MOQ clothing manufactures but the introduction comes with a "be aware" notice. Contact me for more information about how to manufacture clothing in Vietnam.

Why is the MOQ so high?

Imagine one factory with 15 sewing lines (20 sewers per line). Every time the factory has a new order, they need to “set up the line” because each style has different sewing operations. (A t-shirt has 18 operations whereas a mens blaze might have 27 operations. Underwear may only have 12 operations.)

Schedule a Factory Tour Today!

Setting up the line is a non-productive time period because the factory must pay the workers full salary even though the machines are not running at maximum speed. After setting up the line has been completed, it takes 1 – 3 more days to reach maximum productivity. For most factories, the maximum productivity of one sewing line is 900 garments per day. Speed depends on the complexity of the garment style.

If you only order 500 pieces, the factory will finish the order before they are able to reach their maximum productivity. As the client, you will want to calculate labor costs based on maximum productivity, however, the factory will calculate labor costs based on minimum productivity; and therefore will need to charge a high labor cost. Because of this, the benefit to manufacture clothing in Vietnam is now compromised and your company would be better off producing locally. To manufacture clothing in Vietnam you need large quantities.

In contrast, a 20,000 piece order will take one sewing line 22 days to finish. The setup time is short enough that the average productivity per day is very close to the maximum productivity of the factory. The factory can offer labor costs at maximum productivity. When you are able to produce more than 1,000 pieces per style then you are ready to manufacture clothing in Vietnam.

Small MOQ is possible, but!

If you only order 500 pieces, the factory will finish the order before they are able to reach their maximum productivity. As the client, you will want to calculate labor costs based on maximum productivity, however, the factory will calculate labor costs based on minimum productivity; and therefore will need to charge a high labor cost. Because of this, the benefit to manufacture clothing in Vietnam is now compromised and your company would be better off producing locally. To manufacture clothing in Vietnam you need large quantities.

In contrast, a 20,000 piece order will take one sewing line 22 days to finish. The setup time is short enough that the average productivity per day is very close to the maximum productivity of the factory. The factory can offer labor costs at maximum productivity. When you are able to produce more than 1,000 pieces per style then you are ready to manufacture clothing in Vietnam.

Small MOQ is possible, but!

There are factories that will do small MOQ but beware of these factories because:

• They are usually mom and pop operations. Here today, gone tomorrow.

• They don't have additional services like sourcing fabric, sourcing trims or sourcing accessories.

• The day they get a bigger and juicier order, all of a sudden your order will take a back seat.

If your MOQ is below 1,000 pieces, it makes more sense to manufacture your clothes locally. Manufacture clothing in Vietnam when your brand starts to take off, not before.

Are you able to produce more than 1,000 pieces per style?

Do you know your import duty costs and shipping fees?

Are you able to travel to Vietnam and see the factory with your own eyes?

Let's discuss these last two points.

• They are usually mom and pop operations. Here today, gone tomorrow.

• They don't have additional services like sourcing fabric, sourcing trims or sourcing accessories.

• The day they get a bigger and juicier order, all of a sudden your order will take a back seat.

If your MOQ is below 1,000 pieces, it makes more sense to manufacture your clothes locally. Manufacture clothing in Vietnam when your brand starts to take off, not before.

Are you able to produce more than 1,000 pieces per style?

Do you know your import duty costs and shipping fees?

Are you able to travel to Vietnam and see the factory with your own eyes?

Let's discuss these last two points.

How much are the import duty and shipping costs?

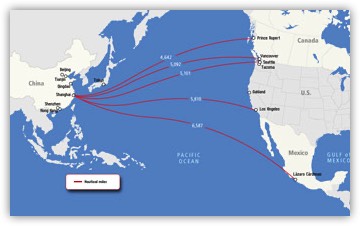

The second question you should ask yourself is: How much are the import duties and shipping costs for my garment(s)? In order to manufacture clothing in Vietnam and import into the USA you will have to pay an import duty. Every country has their own import duty rates and the amount you pay will depend on the garment style and fabric composition. To manufacture clothing in Vietnam you need to know about import duties.

Duty Rate Example: A t-shirt made with polyester fabric has a duty rate of 22% whereas a t-shirt made with 100% cotton has a duty rate of 16.5% - when importing from Vietnam into USA. Let’s say a factory in Vietnam offers you a price of $2.5 USD/t-shirt. This price does not include import duty. The factory will not be able to tell you what the duty (tax) is because they are not certified USA Customs Brokers. You will need to contact freight forwarding companies who have licensed customs brokers on staff; they will be able to help you. To manufacture clothing in Vietnam effectively you should be all over your duty rates.

Duty Rate Example: A t-shirt made with polyester fabric has a duty rate of 22% whereas a t-shirt made with 100% cotton has a duty rate of 16.5% - when importing from Vietnam into USA. Let’s say a factory in Vietnam offers you a price of $2.5 USD/t-shirt. This price does not include import duty. The factory will not be able to tell you what the duty (tax) is because they are not certified USA Customs Brokers. You will need to contact freight forwarding companies who have licensed customs brokers on staff; they will be able to help you. To manufacture clothing in Vietnam effectively you should be all over your duty rates.

Shipping Cost You also need to add the shipping costs. This is where the freight forwarding company takes care of you – for a fee.

The freight forwarding company will offer you a price that includes:

• Picking up the goods in Vietnam

• Getting them on a shipping vessel

• Paying for shipping insurance

• Getting the goods into the USA

• Passing the goods through customs

• Delivering the goods to your warehouse

The price a factory in Vietnam offers you does not include the shipping costs. Contact a local freight forwarding company to get an import duty rate quote.

Bottom line is that your import duty cost and shipping costs might be more than you expected. So much more, that the price offered to you by a local sewing factory is the same or cheaper than the Vietnam price. It is important for you to do some research in advance and to take into consideration all of the costs from making the garments to importing them. Once you know all of your options, you will be able to calculate the benefits of manufacturing in Vietnam versus in the USA.

Ok, now that you are able to do 2,000 pieces and you know your import duty and shipping costs, consider this one last question.

The freight forwarding company will offer you a price that includes:

• Picking up the goods in Vietnam

• Getting them on a shipping vessel

• Paying for shipping insurance

• Getting the goods into the USA

• Passing the goods through customs

• Delivering the goods to your warehouse

The price a factory in Vietnam offers you does not include the shipping costs. Contact a local freight forwarding company to get an import duty rate quote.

Bottom line is that your import duty cost and shipping costs might be more than you expected. So much more, that the price offered to you by a local sewing factory is the same or cheaper than the Vietnam price. It is important for you to do some research in advance and to take into consideration all of the costs from making the garments to importing them. Once you know all of your options, you will be able to calculate the benefits of manufacturing in Vietnam versus in the USA.

Ok, now that you are able to do 2,000 pieces and you know your import duty and shipping costs, consider this one last question.

Do I need to visit the factory in Vietnam?

Do I need to fly to Vietnam? My advice is, yes. It is important for you to meet the owner and walk through the factory before you spend time and money developing samples. I even recommend being there during the development and production phrase. It is risky to trust any factory in any foreign country. Having eyes on the ground increases your chance of success.

Let’s talk some numbers. Let’s say you are producing 5,000 garments and each garment has a cost of $4.5 USD (manufacturing, import duty and shipping cost.) You are looking at an investment of $22,500 to make your goods. Two trips to Vietnam will cost you $6,000 USD.

Your first visit will be for factory visit and development. Your second visit will be a month or two later for production. Are you prepared to spend 21% of your total manufacturing budget on travel? What is the opportunity cost of your time spent in Vietnam as opposed to spending that time at home doing marketing and sales?

Ask someone who has been cheated by a factory. After hearing their story you will understand why I recommend you visit the factory. My opinion is that you will not find a trustworthy business partner in a foreign country via the Internet. It's Russian roulette.

When you are in Vietnam, you will need to have a translator and travel guide to interpret for you and get you from A to B without hassle. Ask me and I will recommend guides for you. They speak English well and have experience in the garment sector.

In conclusion: You are ready to manufacture clothing in Vietnam, when you can produce more than 2,000 pieces per style. You are ready to manufacture clothing in Vietnam when you know your import duty costs and shipping fees. You are ready to manufacture clothing in Vietnam when you have the money to travel to Vietnam and see the factory with your own eyes.

Otherwise, I recommend producing locally first. If you need help sourcing a reliable sewing factory in the US then please ask me. I know one.

Let’s talk some numbers. Let’s say you are producing 5,000 garments and each garment has a cost of $4.5 USD (manufacturing, import duty and shipping cost.) You are looking at an investment of $22,500 to make your goods. Two trips to Vietnam will cost you $6,000 USD.

Your first visit will be for factory visit and development. Your second visit will be a month or two later for production. Are you prepared to spend 21% of your total manufacturing budget on travel? What is the opportunity cost of your time spent in Vietnam as opposed to spending that time at home doing marketing and sales?

Ask someone who has been cheated by a factory. After hearing their story you will understand why I recommend you visit the factory. My opinion is that you will not find a trustworthy business partner in a foreign country via the Internet. It's Russian roulette.

When you are in Vietnam, you will need to have a translator and travel guide to interpret for you and get you from A to B without hassle. Ask me and I will recommend guides for you. They speak English well and have experience in the garment sector.

In conclusion: You are ready to manufacture clothing in Vietnam, when you can produce more than 2,000 pieces per style. You are ready to manufacture clothing in Vietnam when you know your import duty costs and shipping fees. You are ready to manufacture clothing in Vietnam when you have the money to travel to Vietnam and see the factory with your own eyes.

Otherwise, I recommend producing locally first. If you need help sourcing a reliable sewing factory in the US then please ask me. I know one.