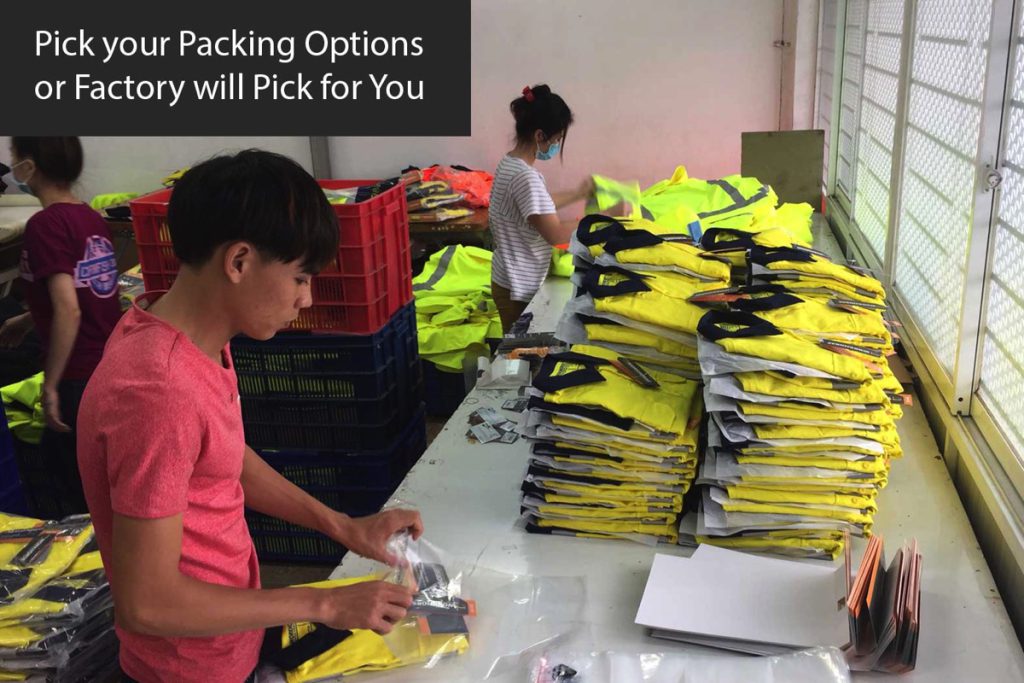

The place to list our your garment packing options, requirements really, is in your tech pack. Here are some of the considerations for garment packing options:

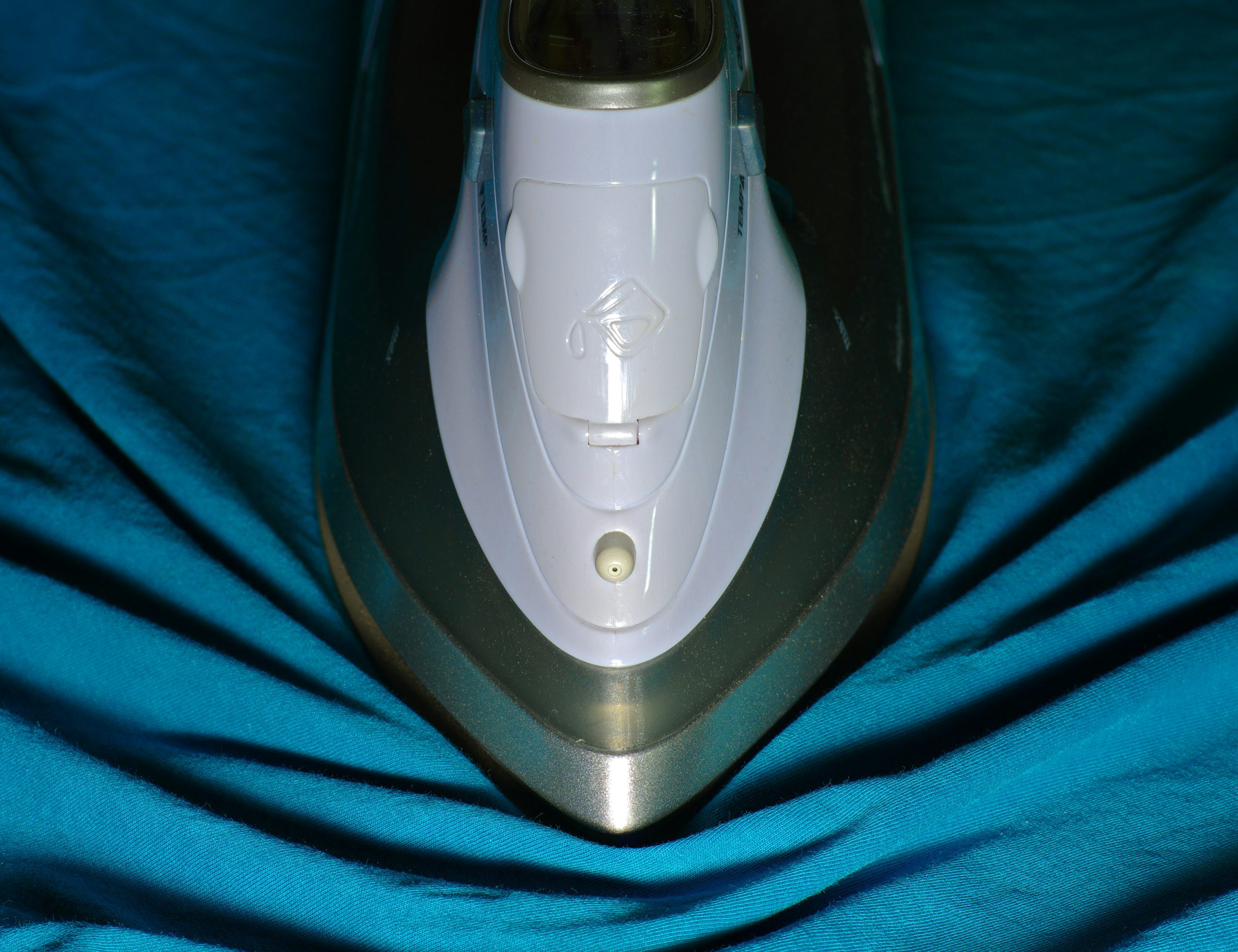

Is ironing necessary?

Does the factory use folding boards?

Is Hanger Packing necessary?

When should I insist on using metal detector?

What questions do you have about garment packing options?

If you need help choosing your garment packing options then ask me.