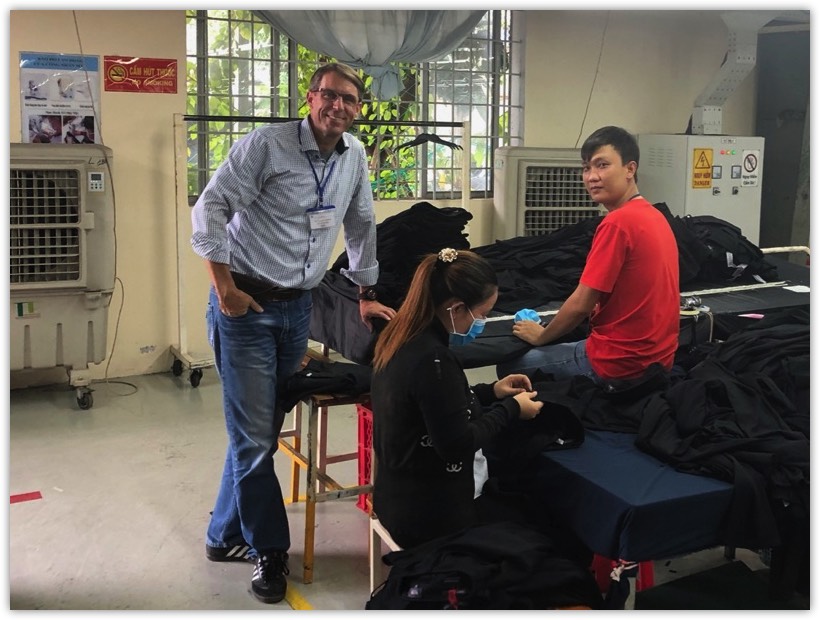

Frank Vossen, Quality Assurance Guru in Vietnam

I started working with Frank in 2017. I consider myself lucky to know and work with Frank in Vietnam because of his business ethics, generous character, and 38 years of doing business in Asia. He is my overseas manufacturing mentor. He is an expert who knows how to get clothing manufactured overseas.

Frank was born in The Congo and grew up in Africa, South America and Europe. Even though his nationality is Belgian, he has a deep understanding of many cultures. He speaks English, French, Dutch, Italian, German, Spanish and a little bit of Vietnamese and Hindi.

This picture was taken in 1992. Frank is on the right with his team of merchandisers, quality controllers and admin staff in Saigon.

Frank joined a Swiss overseas apparel trading company called Sedi at the age of 17. They enrolled him in a 6-month textile quality control course in Switzerland and then stationed him in a Pakistani factory called Aliftex. Frank was in charge of quality assurance for knitting, dyeing, cutting and sewing. His biggest challenge was controlling fabric shrinkage. He learned to manage many variables at different stages of production: the yarn twists, the tension on the knitting machines, the dyeing temperature, the settings on the stentering machines, the cutting process and the sewing technique. He figured out the best way to manage overseas clothing manufacturers is to discover mistakes early, be transparent and report the problems right away to solve them quickly.

His next assignment lasted from 1982 until 1999. Based in Singapore managed overseas production of men’s, women’s and children’s fashion garments for the European mail order industry. Production started in India and over the years expanded to Bangladesh, Nepal and eventually Vietnam. It was particularly challenging working with the cottage industry system in India where the rejection rate was 30%. Frank managed to get it down to 17%. One garment would pass through at least 8 subcontractors before being finished, washed, ironed and packed in the central exporting factory. It was a logistical nightmare that Frank handled with paper trails given that computers weren’t commercially available. Overseas apparel manufacturing is not easy.

In 1989 Frank was the second foreigner to be granted a license by the Vietnamese government to open a representative office. He leased an office, built a team, sourced factories and started shipping containers of clothing to Europe. In those days, business people were assigned a government appointed business escort and could only stay at designated hotels. Frank was a pioneer in Vietnam and knows how to work the system. For example, in 2010 Frank advised his Moroccan investor how to comply with a Vietnamese import restriction that states that second hand garment machinery can only be imported if it is 80% new. Frank knows how to get clothing manufactured overseas.

In 1999, Sedi’s mail order catalogue clients merged and set up their own buying offices. As a result, Sedi saw their business go from $US20 million to $US2 million in less than a year. Frank was assigned the difficult task of visiting Sedi’s 19 partner factories, cancelling agreements which lead to layoffs and factory closures. This experience deeply affected Frank and is one reason he is a compassionate and generous person. Getting clothing made overseas has its ups and downs.

The owner of Sedi retired and Frank decided to get out of overseas apparel trading and focus on quality control. In 2000 he opened a quality control company called Seditex. Given his production experience, he recognized that many quality control inspectors applied AQL very strictly and would unnecessarily stop shipments which was bad for everybody. Having worked in production for more than 18 years Frank understood when it was necessary to follow AQL strictly and when it was necessary to be lenient to complete production, get the customers’ goods to the shops on-time. Frank has trained his QC team to follow AQL standards and at the same time make quick decisions in the factory to keep production moving and meet delivery dates. Frank’s customers include Sears, C&A, Auchan, Dimensions and Men’s Warehouse. He has QC teams in Cambodia, Myanmar, Madagascar and Vietnam inspecting containers of overseas apparel product each month.

Frank’s QC customers ask him for sourcing support so he maintains a sourcing team that can find anything in Vietnam. If you need an overseas manufacturer for shoes, bags, furniture, lingerie, you name it, Frank’s team can find one for you. His sourcing support team offers a la carte services like factory introductions, factory visits, costing, merchandising, factory audits, staff recruitment and workspace hosting.

Frank also works as a business consultant taking on a few challenging projects each year to help businesses set up offices, sell their products or solve difficult problems in Vietnam. One recent example is a foreign accounting firm caught their Vietnamese partner rerouting revenue unfairly. What to do? Frank knew. They hired Frank to handle the sensitive situation. Frank hosted multiple meetings between both parties, created a new legal structure and engineered an ethical asset allocation agreement. After a few weeks, it was clear that the Vietnamese partner was not honoring the amicable split so Frank applied his 30+ years of hands on experience and helped the accounting firm lease a new office, get it furnished nicely and take back the whole team without breaking any laws. What normally would have cost tens of thousands of dollars of lawyer fees and countless days in court, Frank solved quickly and cost effectively. He has faced many sensitive situations like this one and knows what to do. The accounting firm had 60 people working in Vietnam before the situation and now there are more than 100 thanks to Frank. Frank knows the legal boundaries and understands the Vietnamese culture well. He knows how to get clothing manufactured overseas.