Imagine one factory with 15 sewing lines (20 sewers per line). Every time the factory has a new order, they need to “set up the line” because each style has different sewing operations. (A t-shirt has 18 operations whereas a mens blaze might have 27 operations. Underwear may only have 12 operations.)

Setting up the line is a non-productive time period because the factory must pay the workers full salary even though the machines are not running at maximum speed. After setting up the line has been completed, it takes 1 – 3 more days to reach maximum productivity. For most factories, the maximum productivity of one sewing line is 900 garments per day. Speed depends on the complexity of the garment style.

If you only order 500 pieces, the factory will finish the order before they are able to reach their maximum productivity. As the client, you will want to calculate labor costs based on maximum productivity, however, the factory will calculate labor costs based on minimum productivity; and therefore will need to charge a high labor cost. Because of this, the benefit to manufacture clothing in Vietnam is now compromised and your company would be better off producing locally. To manufacture clothing in Vietnam you need large quantities.

In contrast, a 20,000 piece order will take one sewing line 22 days to finish. The setup time is short enough that the average productivity per day is very close to the maximum productivity of the factory. The factory can offer labor costs at maximum productivity. When you are able to produce more than 1,000 pieces per style then you are ready to manufacture clothing in Vietnam.

Small MOQ is possible, but!

There are factories that will do small MOQ but beware of these factories because:

• They are usually mom and pop operations. Here today, gone tomorrow.

• They don’t have additional services like sourcing fabric, sourcing trims or sourcing accessories.

• The day they get a bigger and juicier order, all of a sudden your order will take a back seat.

If your MOQ is below 1,000 pieces, it makes more sense to manufacture your clothes locally. Manufacture clothing in Vietnam when your brand starts to take off, not before.

Are you able to produce more than 1,000 pieces per style?

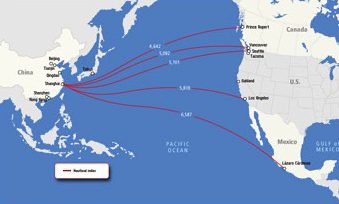

Do you know your import duty costs and shipping fees?

Are you able to travel to Vietnam and see the factory with your own eyes?

Let’s discuss these last two points.