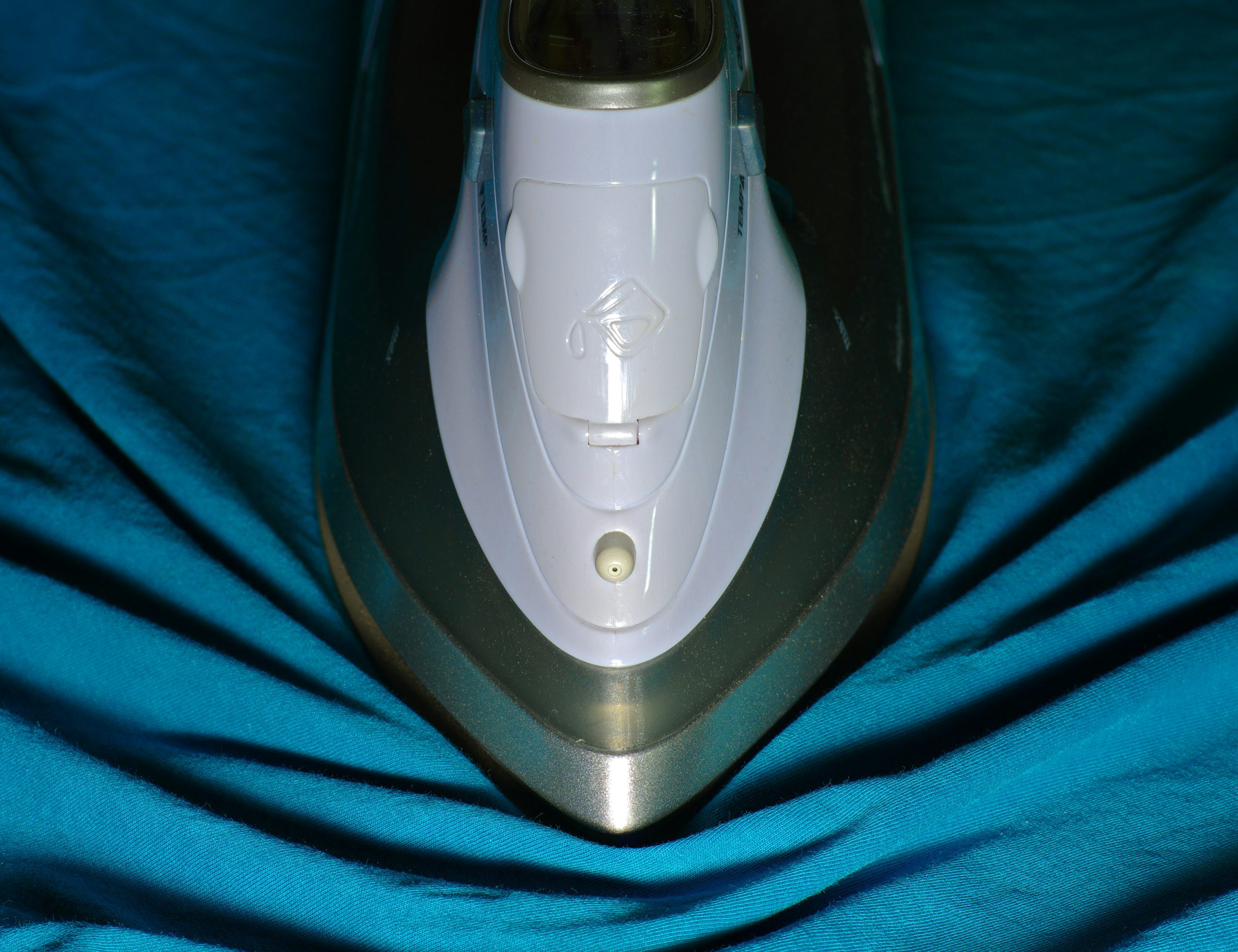

Yes, ironing is necessary for presentation. Especially if the garment is made with cotton and there are natural wrinkles. When was the last time you decided not to buy a garment because it did not look perfect on the rack?

One complication during ironing however, is how it affects the measurements during a final QC check. Ironing stretches out the fabric a little, which might cause it to measure out of tolerance. For this reason, garment measurement should be done by shaking the garment to allow the fabric to relax to it’s natural dimensions. Do you want ironing as a garment packing option?

Another complication, is iron burn! Inexperienced ironers might apply the iron too long and singe the surface of the fabric leaving a permanent mark. When you visit the factory, watch the ironers and check the surface of the fabric. Leaks in the ironing steam piping is common and if not maintained well can cause problems during the ironing process. For example, if they apply too much heat to plastisol prints then the plastisol might melt. This is an example of simple garment packing options that require some thought.