What minimum information needs to be in a garment tech pack in order for a factory to give you a price you can bet on? I receive tech packs from fashion designers and entrepreneurs around the world asking me for a Vietnam manufacturing price. The problem is that 9 times out of 10 their tech packs are incomplete. My message is, if you want an accurate price quote from a factory then I recommend you provide an complete tech pack. The following garment tech pack check list is what I define as a complete tech pack based on my experience working in Vietnam as an apparel production advisor.

1.Flat Sketch

The flat sketch is a two dimensional technical drawing. The flat sketch is just white fill and black outlines. No shading or texture details. There should be sketches of the front, back and any unusual details you consider important. The sketch should be in black and white and drawn to scale as best as possible.

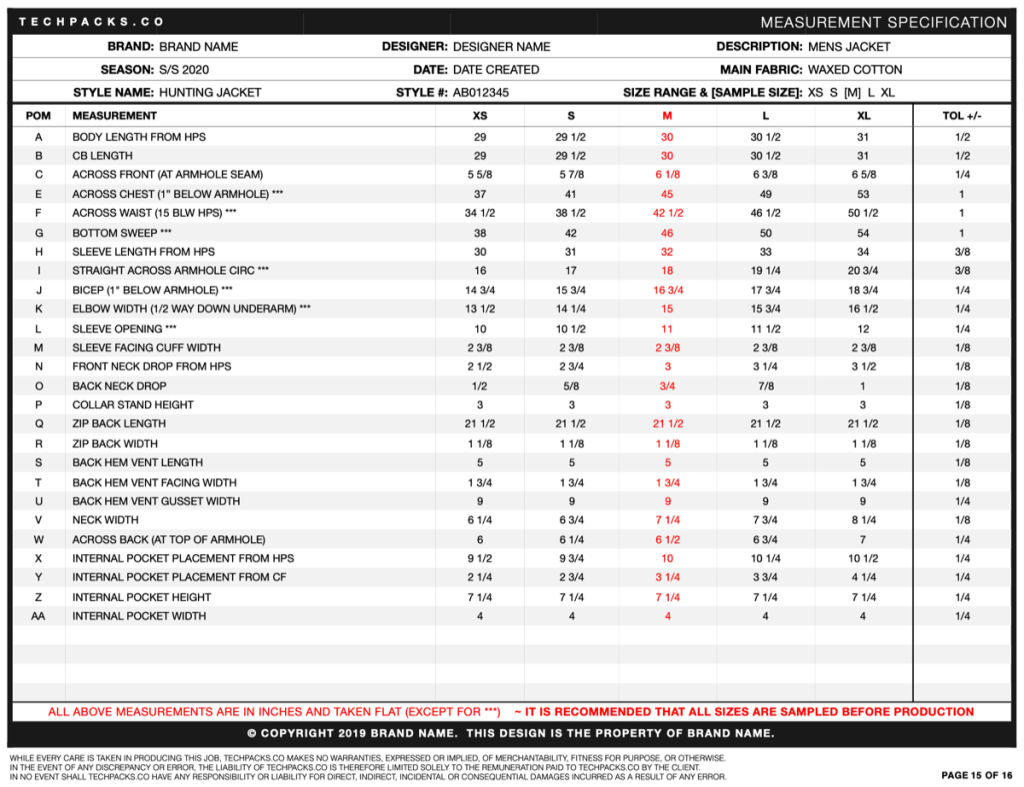

2.Measurement Chart for 1st Sample

I am assuming you don’t have all the size measurements for each size (small, medium, large, XL, XXL, etc.) To get started you must provide the factory with the measurements for at least one size – usually size medium. The factory will use these measurements to make the 1st sample often referred to as the fit sample.

3.Order Quantity Chart

Before the factory can quote you a price they need to know the quantity breakdown for the style (one style per tech pack.) They need to know quantity per color and or quantity per artwork. Let’s say you are making 1,000 black t-shirts with 5 different screen prints. That is 200 pieces per print on the same black fabric. The factory needs to know the quantity breakdown because it affects the price significantly. Quantity per size is not necessary for the initial price quotation.

4.Written or Visual Description

Write down any details about the garment that are not obvious in the sketches. Add more images if you have them. Describe in detail components like collars, plackets, cuffs, fastenings, bar tacks, artwork placement or packing instructions. Describe in detail the silhouette, body, and styling you are expecting.

5.Bill of Materials

The BOM includes everything that needs to be bought to put the garment together. At a minimum you must include the main fabric and any additional fabrics. For fabric, describe the yarn, knit structure, weave structure, weight, Pantone color, finish and width. In addition to fabric, list things like lining, piping, ribbons, shoulder pads, neck tape, thread, buttons, labels, hang tags, hang tag thread, hang tag pins, tissue, poly-bags and desiccant bags. Be as detailed as possible to make sure nothing is overlooked. Make sure you include a column for supplier. If you have nominated suppliers then list the supplier company name.

6.List of Stitches and Seams

If you have any specific stitch or seam requirements then list them here. Illustrate or just write the descriptions of joining operations. Include details like stitches per inch, width of seams, seam allowances, and ISO numbers for each seam.

7.List of Embellishments

If you have any screen prints, embroideries, lace, appliqué, sequins, patches, shoulder pads, stones, or beads then list them here. You can illustrate or just write the descriptions of details like placement, ink type, Pantone colors and stitches per inch for embroidery.

8.Branding Artwork

Here is where you go into detail for anything that has branding on it. Branding usually is placed on labels, hang tags, embroideries or small prints. Show exactly where the branding artwork goes and reference the file name of the artwork. The files will need to be sent separately. Often branding will be combined with care instructions and information like country of origin, RN #s, fabric composition, and detailed washing instructions. Packing includes branding so be sure to include the details of branding on items like poly bags and carton boxes.

9.Measurement Chart for Grading

This section needs to exist but not necessarily filled in. As mentioned early, first the factory will quote price. Then they will make a “1st Sample.” If you decide to go ahead then they will grade your sample from medium size up to, say, XXL and down to say, XS. When they do the grading they will fill in this measurement chart. If you have the grading done in advance then include your complete measurements here. Be sure to include acceptable tolerances for each measurement.

10.Point of Measurement Diagrams

When it comes time to perform a quality control check the factory needs to know where to measure from. They need to be on the same page as you. Use illustrations to show clearly where you expect them to measure to check if the measurements are within tolerances.

11.Headers on On Every Page

Be sure to include your company or brand name, name of designer, the style identifier, size range, sample size, the date and version number on each page.

12.List for Tracking Changes

Create a list that is empty and ready to receive comments and or changes as the development progresses. Include a column for comment/change, person in charge, date, action plan, and deadline.

If there is anything you don’t know from the list above then add the comment “to be discussed with factory.”

Creating a complete tech pack is not easy.

If you take short cuts when it comes to preparing the tech pack, then can the factory take short cuts when it comes to quoting price? Garbage in, Garbage out, right?

Creating a complete tech pack requires technical training and experience.

If you wing it and create what you think will suffice then you are setting yourself up for failure. My advice is to have your tech packs created by a professional in your country before you send to Vietnamese factories. Professional tech pack creators know the minimum information needs to be in a garment tech pack and they can help you fill in gaps that you are not sure about.

What is the dollar value of a tech pack?

How much does it cost to have a tech pack made? I use www.techpacks.co as a reference point. See their pricing for your reference. Generally speaking a tech pack dollar value is $1,000. If you don’t have tech packs, then do you expect the factory to create them for you? Does that mean you are asking the factory to do $1,000 dollars of free work? How would you feel if someone asked you to do $1,000 dollars worth of free work. If you have your tech packs made in advance and they are professional and complete, then your chance of success increases exponentially! And you put yourself in a better bargaining position because the factory respects you as a professional.

How do tech packs save you time and money in the long run?

First, know that a good factory will be able to quote an accurate price and make a sample from a complete and professional tech pack. Getting an accurate price and good sample puts you on third base quickly.

Second, you can send your tech packs by email, for free, to factories in Mexico, Peru, China, India, Vietnam and Sri Lanka simultaneously – and 4/10 will reply back with a price. You save money by not having to fly to all these countries. Now you have a few prices and you know you are comparing apples to apples, plus, you know that the 4/10 that replied are seriously interested in your order. At this point you can ask the 4 to make counter samples and they might just do it for free! Now you’ve got pricing, you’ve got counter samples and you can pick the one you like best. It’s faster and cheaper in the long run to invest $1,000 upfront to have your tech packs made professionally and then use the power of email as opposed to traveling to all countries and trying to develop the samples on-site using the factories precious manpower and resources. Not to mention your cost in time and energy.